Schreiben Sie uns!

Rufen Sie uns an!

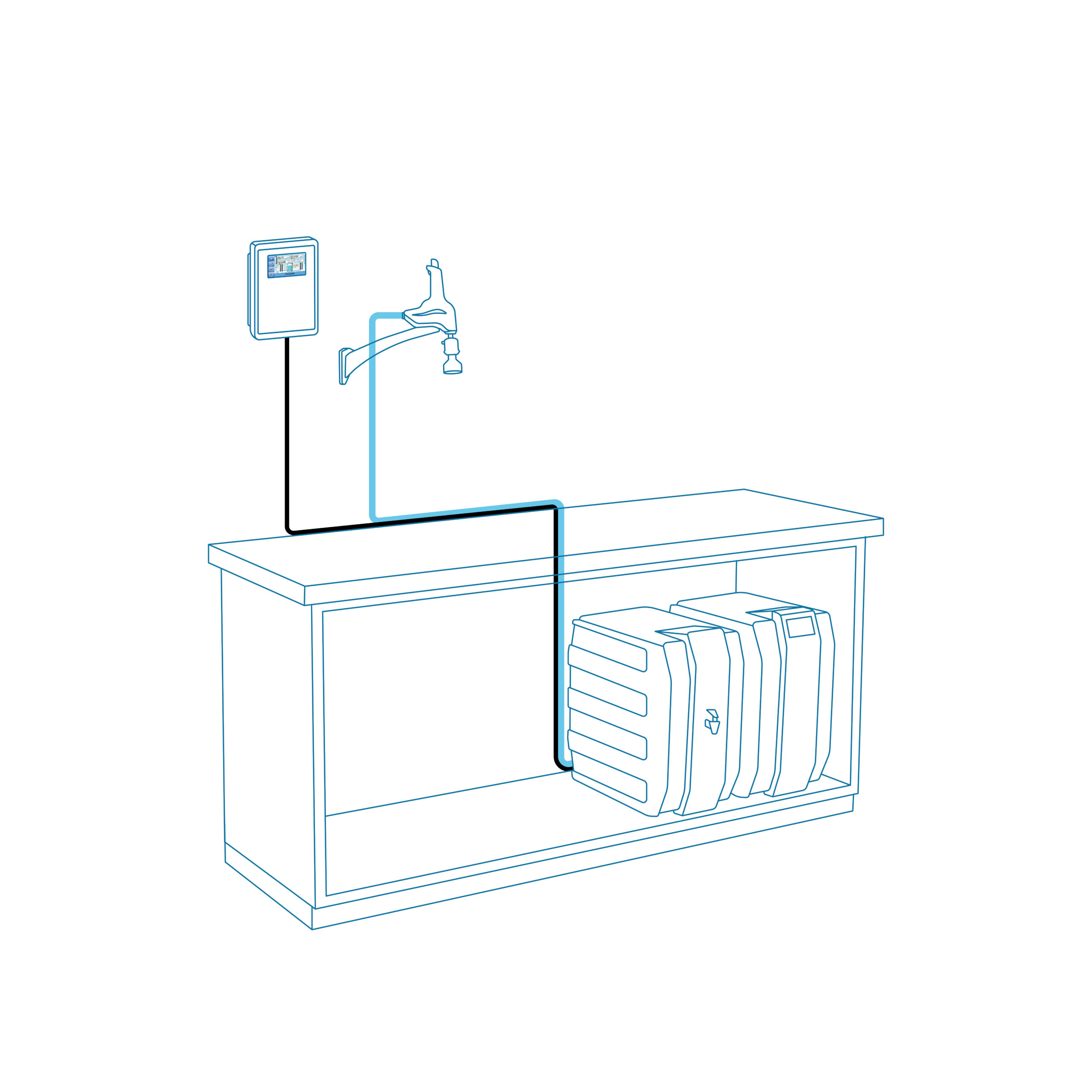

The scheme shows the setup of an AquaRO² DI with a capacity of 10 or 20 L.

To save valuable benchtop space the system can be ordered as BI configuration. The system will be installed underneath the work bench and only the display and dispenser are mounted on the wall.

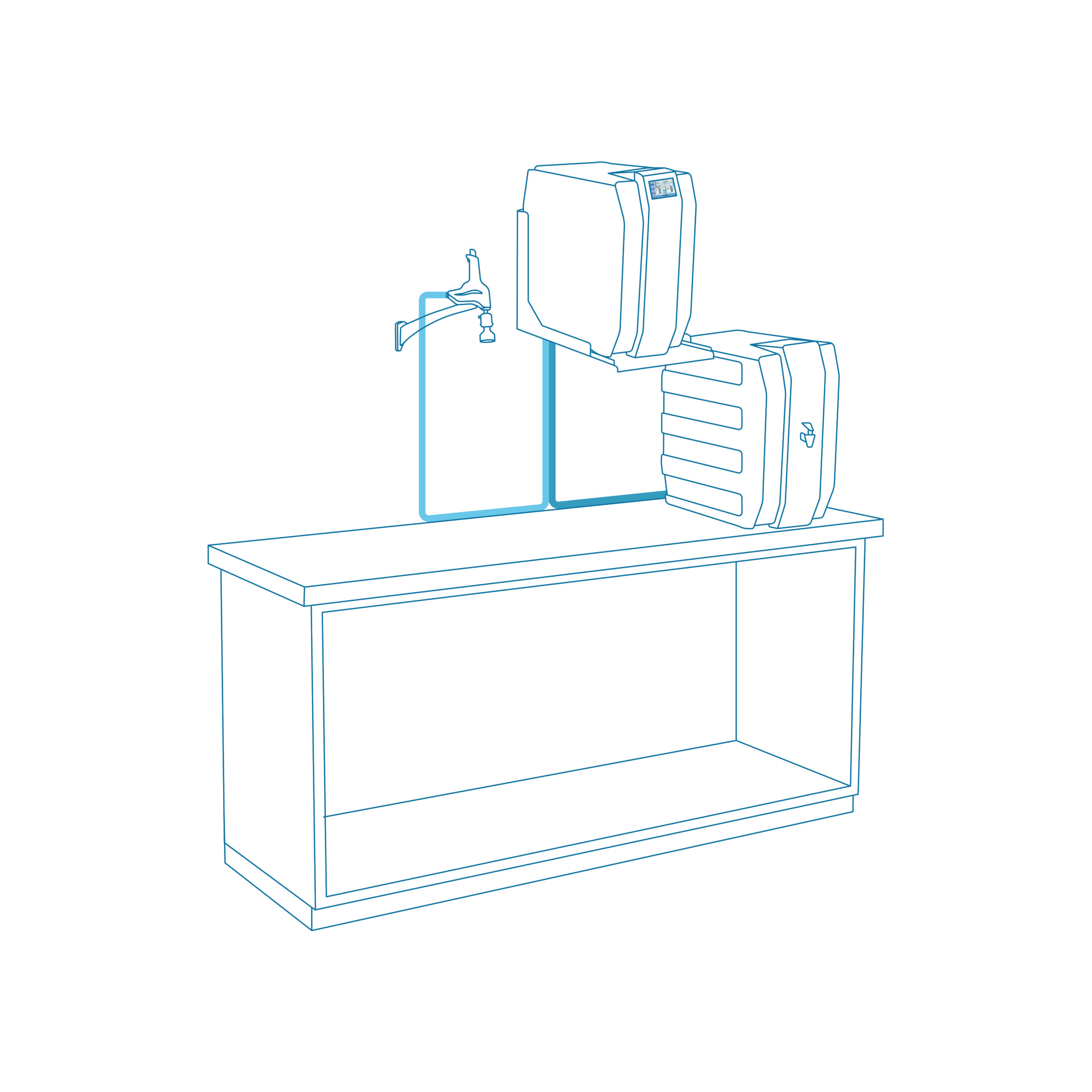

To save valuable benchtop space the system can be ordered as wall mounted configuration. the whole system can be mounted on the wall with inclined display.

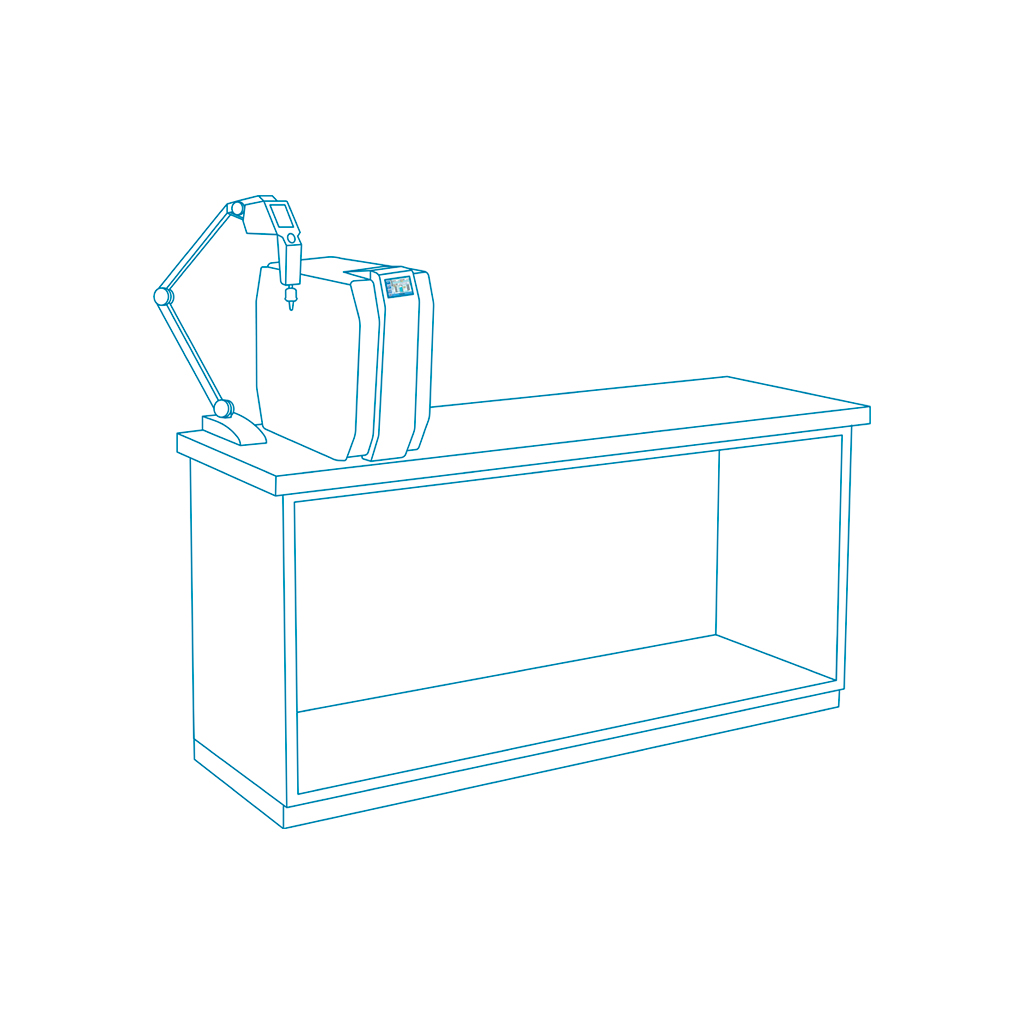

Compact pump is required when feeding laboratory equipment such as autoclaves or laboratory dish washers.

The TOC monitoring during production and intermittent measurements during non-use periods allows to check the organic content in water continuously. The TOC value is measured between 1 and 999 ppb and can be shown in the display to monitor organic impurities.

Our dispenser for the series of AquaRO² 8 P10 allows the volumetric controlled dispensing of water with an increment of 0.1 L and a tap volume from 0.1 to 99 L. The system prevents overflow of containers and allows to dispense water without supervising.

The series of AquaRO² and EDI² can be equipped with a tank of 35 L or 70 L or individual size (up to 500 L) and if requested also with an integrated UV lamp. An exception is the AquaoRO² 8 P10 with an integrated tank of 10 liters.

Validation documents for water purification systems.

| Technical Specifications | ||||

|---|---|---|---|---|

| Model | AquaRO² | AquaRO²DI | AquaRO² 8 P10 | P10 DI | EDI² |

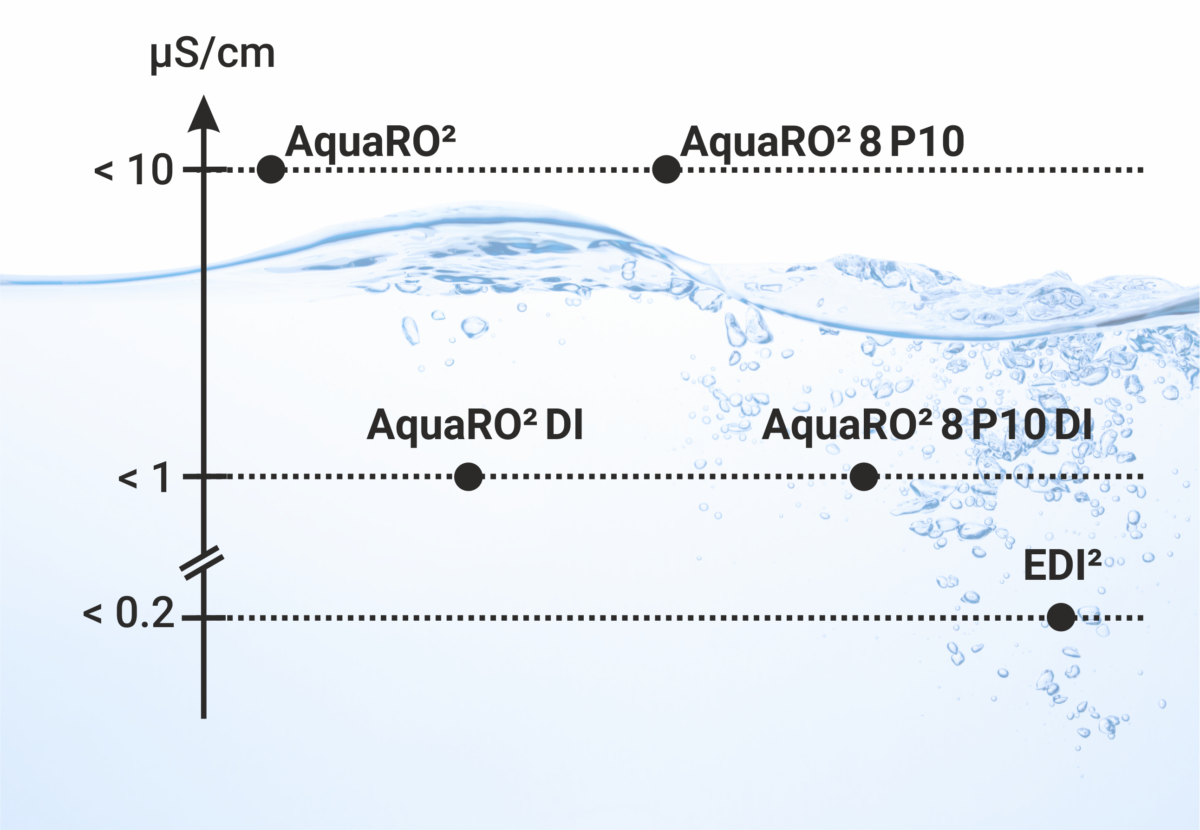

| pure water quality | < 10 µS/cm | < 1 µS/cm; Type II | < 10 µS/cm | < 1 µS/cm | < 0.2 µS/cm; Type II |

| resistivity | > 0.1 MegaOhm/cm | > 0.5 MegaOhm/cm | > 0.1 MegaOhm/cm | > 0.5 Megaohm/cm | > 5 MegaOhm/cm |

| total organic carbon (TOC) | < 50 ppb | < 40 ppb | < 40 ppb | < 20 ppb |

| production rate | 8 L/h to 40 L/h | 8 L/h to 20 L/h | 8 L/h | 10 L/h to 40 L/h |

| bacteria | < 50 cfu/mL | < 50 cfu/mL | < 50 cfu/mL | < 10 cfu/mL |

| DNAse | < 5 pg/mL* | |||

| dimensions, weight, power (except AquaRO² 40 and EDI²40) | ||||

| AquaRO²: 504 x 340 x 535 mm, 16 to 20 kg, 110 V - 230 V | ||||

| EDI²: 504 x 340 x 535 mm, >40 kg, 110 V - 230 V | ||||

| Feed Water Requirements | ||

|---|---|---|

| Model | AquaRO² | EDI² |

| type of feed water | potable water / tap water | potable water / tap water |

| feed water conductivity | < 1400 µS/cm | < 1400 µS/cm |

| inlet pressure | 1.5 to 6 bar | < 5 bar |

| free chlorine | < 0.1 mg/L | < 0.02 mg/L |

| Silt Density Index (SDI) | < 3 | < 3 |

| pH | 3 to 9 | 3 to 9 |

| temperature | 5 to 25 °C | 5 to 25 °C |

| iron / manganese | n. a. / n. a. | < 0.01 mg/L / < 0.01 mg/L |

| sulfate | n. a. | < 2 mg/mL |

Both systems are laboratory water systems which provide the user with different qualities of pure water for a wide range of analytical and laboratory applications.

These systems are AquaRO² systems with an integrated 10 L tank that holds the treated water and then makes it available to the user via a dispenser.

Depending on the configuration, an AquaRO² system produces pure water with an electrical conductivity of between 0.2 and 10 µS/cm, while the EDI² systems achieve a value < 0.1 µS/cm. Most systems are fed with drinking water.

The compact design means that each of the systems takes up very little valuable laboratory space, and their simple and intuitive operation makes them easy to integrate into everyday laboratory work.

Customers have the option of selecting a system with a production capacity of 10 to 40 liters per hour, depending on the application and water requirements.

Due to the simple and clear design of the software, the user can quickly operate the device through intuitive handling. The software informs the user when limit values have been exceeded or when consumables such as cartridges or UV lamps need to be replaced. A wizard guides the user through the individual steps.

In addition to the hoses for inlet and outlet, an adapter is also included in the scope of delivery, which makes it easy for them to adapt the systems with the drinking water connection or to an inlet with pre-treated water.

Depending on the choice, the systems can be supplied with a 35 or 70 liter tank. There is also the possibility to offer tanks with a capacity of 100 L to 500 L. Each tank has a bottom outlet so that external systems such as analyzers or ultrapure water systems can be fed directly. On request, a booster pump can also be offered to pump the water.

The installation location can be designed very flexibly. Depending on the available work surface, the system can be integrated directly on the equipment, on the wall or under the lab bench. The display, which can be installed flexibly, also ensures convenient operation.

We would like to improve the contact to our customers & partners and send you information and updates about our company and our products

membraPure endeavours as far as reasonably possible to provide correct and complete information on this website. However, membraPure does not guarantee that the information provided is up-to-date, correct and complete. The same applies to the content of external websites that this site refers to directly or indirectly via hyperlinks, programmes, files, contents or hyperlinks to other websites are provided without any expressed or implied warranty.

Contact Us

membraPure reserves the right to alter the information provided on this site without prior notice.

membraPure GmbH, Wolfgang-Kuentscher Str. 14, 16761 Hennigsdorf