Determination of Anions in an Amine Solution Using the IONUS Ion Chromatograph

Amine solutions are used in refinery boilers to prevent corrosion and scaling, and in crude oil processing to capture carbon dioxide (CO2) and hydrogen sulfide (H2S) from industrial flue gases. The captured CO2 can be repurposed and used in enhanced oil recovery, chemical production, carbonation of beverages, or storage for future use. The captured H2S can be converted into elemental sulfur, or used as a feedstock in the production of other sulfur-containing chemicals.

Impurities in the flue gas react with the CO2 and H2S to form various ionic species, such as anions. The anions formed in the reaction can degrade the amine capture solution, cause corrosion, and affect the captured CO2 and H2S.

Why Analyze for Anions in Amine Solutions?

Routine analysis of anions in refinery amine solutions gives important data for optimizing CO2 and H2S capture processes and provides data to ensure amine solution effectiveness. Here’s why monitoring anion concentration levels are critical:

- Maintaining Optimal CO2 Capture Efficiency: The presence of anions in the amine solution can reduce the absorption of CO2. By monitoring anion levels, operators can ensure the solution remains within optimal concentration ranges for efficient CO2 capture.

- Efficient Capture of H2S: The presence of anions in the amine solution can hinder the capture of H2S, which can be converted to elemental sulfur or additional feedstock.

- Preventing Fouling: Anions can contribute to the formation of heat-stable salts within the processing unit. These inorganic salts can lead to corrosion of pipes and equipment, as well as fouling of heat exchangers, increasing costs and negatively impacting operations. Early detection of anions allows the refinery operators to take appropriate actions, such as replacing the amine solution or implementing cleaning procedures, to prevent these issues.

Therefore, analyzing the concentration of anions in the amine solutions is crucial for maintaining optimal performance of the CO2 and H2S capture process, as well as minimizing the potential for environmental issues.

Optimizing the Amine Processes: The presence of anions in the amine solution would determine either full replacement of the amine solution, at considerable cost, or regenerate the amine solution. An electrodialysis technique can be used to remove impurities and regenerate spent amine solutions. Analyzing the anion content before and after regeneration helps monitor the effectiveness of the electrodialysis process and allows for adjustments to maintain its performance. This ensures the regenerated amine solution remains free of harmful anions for continued efficient CO2 and H2S capture.

Common Anions Found in Amine Solutions

The presence of anions in amine solutions can negatively impact CO2 and H2S capture processes. Let’s look at some of the common anions and the issues they cause.

Inorganic Anions:

Chloride (Cl−) and Sulfate (SO42−): These are often introduced through the makeup water used in the capture system. Their presence reduces CO2 and H2S absorption capacity and can contribute to heat-stable salt formation, leading to corrosion and fouling.

Organic Anions:

Formate (HCOO−) and Acetate (CH3COO−): These are breakdown products from the degradation of the amine itself during operation at high temperatures. They exhibit similar negative effects on CO2 and H2S capture efficiency and equipment integrity as inorganic anions.

Oxalate (C2O42−), Thiosulfate (S2O32−), and Thiocyanate (SCN−):

These anions can also be present in amine solutions, potentially originating from degradation products or specific contaminants in the flue gas. While less common than chloride or formate, they can still contribute to efficiency losses and require monitoring.

The specific types and concentrations of anions will vary depending on the source of the amine, the makeup water, and the operating conditions of the capture plant. However, by regularly monitoring these contaminants, plant operators can take the appropriate actions to maintain standard operations for CO2 and H2S capture performance and minimize equipment problems.

Operating Conditions of the Method

| IC System | IONUS Ion Chromatograph |

| Column | Si-90-4E (4mm x 250mm) |

| Eluent | 1.8 mM Sodium Carbonate / 1.7 mM Sodium Bicarbonate |

| Suppressor | membraPure IC Suppressor² |

| Sample | Dilution and filtration with IC syringe filters |

| Injection | 20 µL |

| Water Source | Aquinity² P10 Analytical (0.055 µS/cm, Type I) |

Sample Preparation

The sample represents a prepared 40% Amine concentration in the sample with the following analytes spiked into the prepared solution:

| Analyte | Concentration |

| Acetate | 1000 ppm |

| Formate | 500 ppm |

| Chloride | 250 ppm |

| Sulfate | 500 ppm |

| Oxalate | 250 ppm |

| Thiosulfate | 10000 ppm |

| Thiocyanate | 10000 ppm |

The actual concentrations of anions injected into the IONUS after a 1:100 dilution were:

| Analyte | Concentration |

| Acetate | 10 ppm |

| Formate | 5 ppm |

| Chloride | 2.5 ppm |

| Sulfate | 5 ppm |

| Oxalate | 2.5 ppm |

| Thiosulfate | 100 ppm |

| Thiocyanate | 100 ppm |

MDEA is the Amine used as the “amine” stock. Anions were spiked into a 4.5% MDEA solution to represent a 1:100 dilution of a working sample.

The texture is an aqueous representation of a diluted MDEA spiked and filtered with a 0.22-micron IC-specific filter. The starting MDEA is a 99% chemical purchased from Aldrich Chemicals. Unlike a real sample from the oilfield or chemical plant, this MDEA didn’t have particulates. The sample was treated as if particulates were present by diluting and filtering it to emulate the process a sample would go through in the laboratory before analysis.

The sample was then diluted in ultra-high purity deionized water from the Aquinity P10, filtered through a 0.22um IC filter into a 2 mL vial with a septa cap. The sample was loaded into the membraPure autosampler for analysis. The results were evaluated and calculated by the software Clarity (DataApex).

Unmatched Performance for Anion Analysis in Amine Solutions:

The membraPure IONUS IC Advantage

Accurately measuring anions in amine solutions is crucial for optimizing CO2 capture processes. The membraPure IONUS Ion Chromatograph stands out as the ideal solution for this demanding application. Here’s why:

- Exceptional Precision: The IONUS delivers unmatched precision through its:

- Advanced Eluent Delivery system: Guarantees consistent eluent flow, a critical factor for reliable separation of various anions.

- Precise Temperature Control: Maintains a stable column temperature, ensuring optimal peak resolution for accurate identification and quantification.

- Accurate Sample Injection: Delivers a precise volume of your amine solution every time, minimizing errors and maximizing data reproducibility.

- Advanced Detector Cell: Provides exceptional signal stability, leading to reliable and consistent anion detection.

Optimized Separations: The IONUS goes beyond precision with its:

- Next-Generation IC Suppressor: This innovative technology significantly enhances the separation of anions commonly found in amine solutions. The suppressor improves the analysis of Acetate, Formate, Chloride, Sulfate, Oxalate, Thiosulfate, and Thiocyanate in the amine solution.

- Proven Analytical Column: The robust and reliable column ensures efficient separation and long-lasting performance for your amine solution analysis.

By combining exceptional precision with optimized separations, the membraPure IONUS empowers you with the confidence to make informed decisions about your CO2 capture process.

Benefits of Utilizing the IONUS Ion Chromatograph for this Application

The membraPure IONUS Ion Chromatograph is best suited for the application of measuring various anions in an amine solution because of the following:

- Performance: The precision delivery of the eluent, the stable temperature of the column temperature, the accurate delivery of the sample into the system, and the stability of the detector cell all contribute to the quality analysis of the anions in the amine solution. With the introduction of our new IC Suppressor and the utilization of a rugged, proven, analytical column, the separation is optimal for this application on the IONUS.

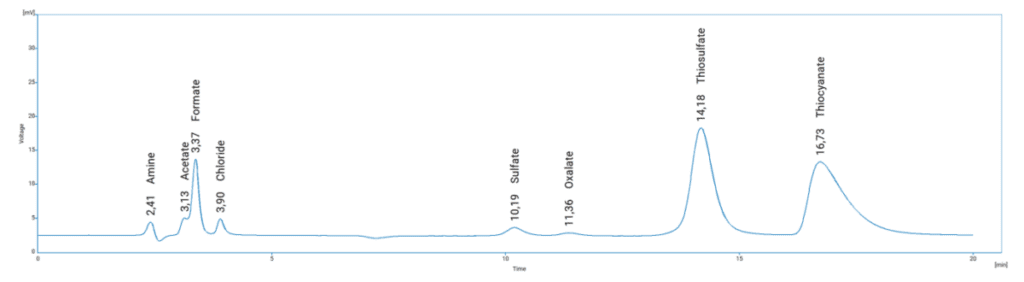

Figure 2: Resulting chromatogram of the analysis of the anions acetate, formate, chloride, sulfate, oxalate, thiosulfate and thiocyanate in the amine solution

- Reliability: Measuring anions in amines is critical to the life of the amine process. The instrument selected needs to perform when needed without issue. The IONUS is the proven performer as it automatically rinses and equilibrates itself prior to the first injection, assuring the analysis is reliable from the start.

- Easy to Use: The IONUS will be installed by a qualified engineer. Once operational, the analysis will be as simple as Dilute, Filter, Load, and Go. Many labs are manned by technicians, not degreed chemists. Therefore, the more simple and reliable the operation, the faster qualified data can be produced. It really is just that simple.

- ROI: Yes, companies want an instrument that delivers optimal return on their investment, and the IONUS is the choice Ion Chromatograph to deliver not just the best result, but the best ROI! The German-made, German-produced IONUS will be working and producing quality data long after others are being replaced.

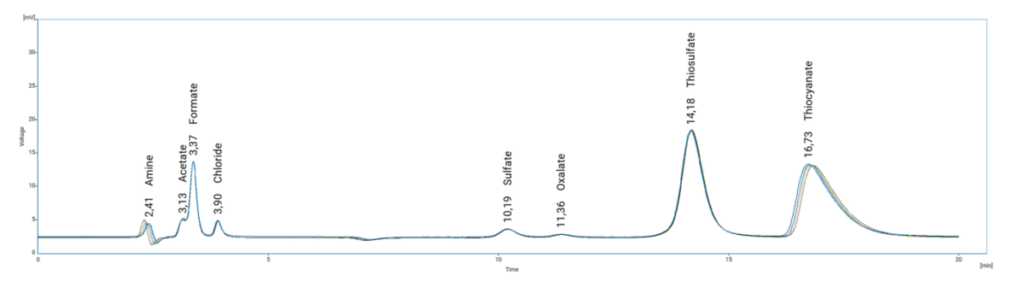

Rigorous Validation for Reliable Results:

To ensure the application’s effectiveness and demonstrate the IONUS Ion Chromatograph’s exceptional reproducibility, we analyzed anions in amine solutions under various IC conditions. This rigorous validation process confirms the consistent and reliable performance of the instrument for your specific needs.

Streamlined Workflow for Simplified Analysis:

The membraPure IONUS prioritizes user experience with its intuitive design. Here’s how it simplifies your anion analysis in amine solutions:

Minimal Sample Preparation: Sample preparation is a breeze – just dilute your amine solution and filter it into a standard vial. No complex procedures are required.

Automated Analysis: With a few clicks, you can set up your sample sequence and quality control standard in the user-friendly chromatography software. The IONUS then takes over, analyzing your samples, the standard, and reporting results automatically.

Simplified System Maintenance: The instrument takes care of itself! The IONUS automatically prepares the columns, regenerates the suppressor, and performs rinses before each injection, ensuring optimal performance and minimizing manual intervention.

Results

Additional application work was performed to optimize the application. Testing multiple columns, flow rates, temperatures, injection volumes, eluent components, concentrations, and molarities. The end result is the application being presented as the best possible conditions for the highest level of performance of the Anions in an Amine Solution application. The synthetic sample takes into account Chloride at the possibility of 250 ppm. Iron would not be seen but over time would accumulate on the column pre-filter forcing replacement. Any accumulation on the suppressor would be reduced by frequent flushing. H2S would also not be a factor in this analysis unless it converted to Sulfite or Sulfate in the Carbonate-based eluent after injection. It is doubtful H2S would have any real contribution to the overall analysis.

If iron is any real concern, a syringe cartridge could be used to prepare the sample by removing the iron, but it may also remove something else of interest.

What is the minimum and maximum limit of detection for the method?

The minimum limit of detection in the actual sample is estimated to be mid-ppb for all analytes. Here is why mid-ppb detection is possible:

- A 20 µL injection was used. By increasing the injection volume to 50 µL improvements in detection limits would be possible without any reduction of separation. Our lab performed this analysis at 20 µL and 50 µL.

- The baseline is quiet so we can easily go lower in our detection.

- The new membraPure suppressor2 provides sharp peaks and better resolution than the previous suppressor thus improving detection capability.

- Temperature stability of the IONUS column compartment and detector.

The maximum limit of detection is easily 10-20x higher (maybe higher) than what has been reported and will be investigated in a further application note. Acetate will eventually start co-eluting with Formate with less capability to resolve them. Working with the known capability of the IONUS, the excellent separation capability of the analytical column, the improvements in the suppressor, and the temperature stability, all working together to deliver a resolved separation even with higher concentrations. Optimizing the loop injection for the higher concentrations will help maintain a fine balance between the Acetate and Formate.

The simple operational protocol of the IONUS with a 1:100 ‘dilute, filter, and shoot’ sample prep allows for optimal performance. Injecting higher concentrations or using a lower dilution protocol may be possible but risks co-elution of Acetate and Formate. All other analytes can increase accordingly as the method presented on the IONUS has the resolution and the capacity to handle the increased concentration.